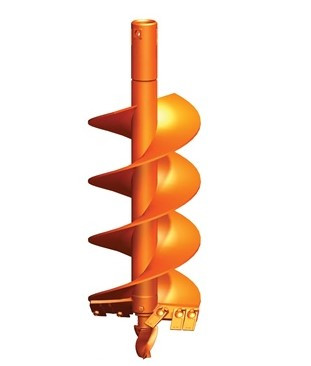

Best Tips For Bobcat Auger Replacement Teeth

Best Tips For Bobcat Auger Replacement Teeth

If you are going for Bobcat auger replacement teeth, be smart. The market out there is ruthless for buyers without knowledge. You will find people that are ready to sell you anything immediately they realize you have no idea of what you want. Fortunately, there are ways that you ensure that you are getting the right replacement parts.

Read on to learn some of the best Bobcat auger replacement teeth tips for beginners. These are tips that will help you get perfect parts for your Bobcat auger. If you are going to the market, look for the following:

Teeth Size

One of the crucial factors that you must get right is the teeth size. You must ensure that you are getting the right size for the machine. This is a very important factor because it determines the effectiveness’ of the auger upon making the replacement. If buying for the first time, check what the manufacturer has provided in the user manual. You will get the details of teeth size.

Type Of Drilling

The second thing to consider to get Bobcat auger replacement teeth is the type of drilling conditions. There are all kinds of drilling in the industry, and all of them may have different specifications. Drilling loose soil will not be the same as drilling rocky soil. So you need to know the kind of drilling that you want to do to get the right replacement teeth.

Quality Of Parts

You must always check the material that has been used for the construction auger teeth. One of the things that you need to check is the quality of materials. Both the body and the tips of the teeth must be of good quality that can withstand rough drilling conditions. This is a very important factor to consider.

Tip Sharpness

The sharpness of the teeth tip and ability to withstand heat and abrasive condition matters a lot. That is why it is important to ensure that the right material has been used for the tip. There are many materials used for the Bobcat auger replacement teeth tips, but tungsten carbide is the most widely used. It has the best mechanical features.

Hardening

Make sure that you have checked the hardening technique used during the manufacturing process. This is a very important factor because it will determine the quality of Bobcat auger replacement teeth. The quality hardening process produces quality auger teeth.