Best Flexo Platemaking Tips For New Manufacturers

Flexographic printing has gained significant popularity due to its versatility and cost-effectiveness. As a new manufacturer entering the flexo printing industry, it is crucial to understand the importance of high-quality flexo plates in achieving excellent print results. To help you navigate this process effectively, we have compiled five essential tips for new manufacturers venturing into flexo plate making.

Choose the Right Plate Material

The choice of plate material significantly impacts the quality and durability of your flexo plates. There are various plate materials available, including photopolymer, rubber, and others. Photopolymer plates are widely used due to their versatility and excellent print reproduction. Consider factors such as ink compatibility, substrate type, and print run length when choosing the plate material.

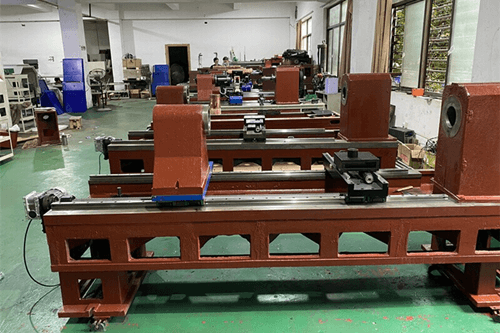

Invest in High-Quality Imaging Technology

Investing in advanced imaging technology is essential to ensure accurate reproduction of intricate details on plates. Advanced technology enables you to create plates with sharp images, smooth gradients, and fine line work. Partnering with a reputable plate manufacturer who utilizes cutting-edge imaging technology can significantly enhance your plate making process.

Pay Attention to Plate Thickness

Plate thickness plays a crucial role in determining print quality and ink transfer. Choosing the appropriate plate thickness depends on the type of substrate, ink viscosity, and impression settings. Thicker plates provide better ink laydown and are suitable for printing on rough or uneven surfaces, while thinner plates are more suitable for smooth substrates. It is essential to experiment and conduct thorough testing to determine the ideal plate thickness for your specific printing needs.

Optimize Plate Processing Parameters

Maintaining consistent and optimized plate processing parameters is key to achieving high-quality flexo plates consistently. Factors such as exposure time, plate washout, and drying conditions significantly impact plate quality. Follow the guidelines provided and perform regular checks to ensure accurate exposure times. Implementing a robust quality control system to monitor these parameters.

Prioritize Plate Handling and Storage

Proper plate handling and storage practices are crucial to ensure the longevity and reusability of your flexo plates. Always handle plates with clean gloves to prevent fingerprints or contamination. Store plates in a cool, dry, and dust-free environment, away from direct sunlight or extreme temperatures.

Click here for the best and experienced flexo plate makers manufacturers in the market.