Advanced Safety Systems for Modern Industrial Plants

Advanced Safety Systems for Modern Industrial Plants

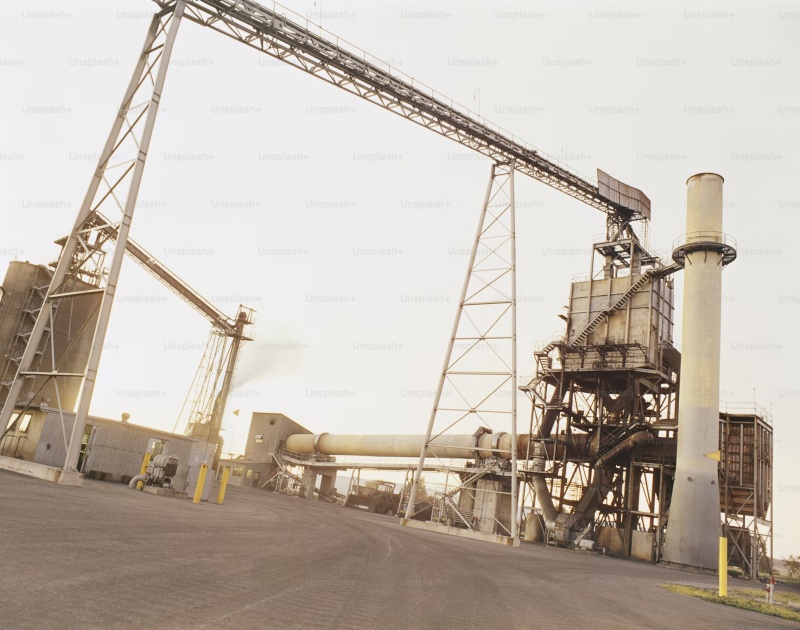

Stringent laws push for more safety systems in industrial plants. Although prevention practices are in place, the presence of complex machinery and hazardous materials make a 100%-safe plant seem impossible.

These dangers that threaten lives and the environment on different scales beg for advanced safety systems. With modern technology, industrial factories can become smarter and safer. Some of these systems may include sensors, automation mechanisms, or a combination thereof.

We listed below some advanced safety systems and how they work in tremendously improving safety in industrial settings.

Real-Time Monitoring Systems

Modern safety systems rely heavily on real-time monitoring to keep track of everything happening on the plant floor. Sensors placed throughout the facility monitor parameters like temperature, pressure, vibration, and gas levels. If something goes out of range, an alert is sent immediately.

- Temperature sensors can detect overheating equipment and prevent fires.

- Gas detectors identify leaks before they become dangerous.

- Vibration sensors monitor machinery to predict potential failures.

The data collected by these sensors is processed by printed circuit boards (PCBs) embedded in control systems, ensuring quick responses to any abnormalities.

Emergency Shutoff Systems

Emergency shutoff systems are designed to stop operations instantly when something goes wrong. They prevent damage to equipment and protect workers from harm. These systems are often integrated with other safety tools, like fire suppression systems or gas leak detectors.

- Shutoff valves stop the flow of hazardous materials during a leak.

- Automated power cutoffs shut down machinery when a risk is detected.

- Fire suppression systems activate immediately when heat or smoke is detected.

Having a fast and reliable emergency shutoff system is a game-changer for high-risk environments.

Automation and AI-Driven Safety

Automation has made plant safety smarter. Automated systems analyze data, predict risks, and sometimes take action without waiting for human input. AI tools are even better, as they learn from past incidents to improve future safety.

- AI-powered tools predict equipment failures based on usage patterns.

- Automated inspections catch safety hazards like loose bolts or misaligned machinery.

- Machine learning algorithms analyze accident data to identify trends and weak points.

By automating safety checks and responses, plants reduce human error and speed up reactions.

Worker Safety Enhancements

Safety isn’t just about machines. Protecting workers is just as important. Advanced safety systems now include tools specifically designed to monitor and protect the people on the plant floor.

- Wearable devices track worker locations and alert them if they enter restricted zones.

- Proximity sensors stop equipment if a worker gets too close.

- Communication systems provide instant alerts to employees during emergencies.

These tools ensure that safety measures are always worker-focused and practical.

Training and Awareness Tools

Even the best safety systems are useless if workers aren’t trained to use them. Many modern safety tools include training modules to keep employees informed.

- Virtual reality (VR) simulations train workers for emergencies in a risk-free environment.

- Interactive dashboards help employees understand plant safety metrics.

- Mobile apps provide quick access to safety protocols and guidelines.

Combining technology with training ensures that safety measures are effective in real-world scenarios.

Final Thoughts

Advanced safety systems are transforming how industrial plants operate. They create safer environments for workers and equipment alike.

Tools specially made for real-time monitoring, emergency shutoffs, and AI-driven automation can help plants prevent potential risks before they become actual problems. With PCB assemblies at the heart of these systems, the technology driving safety continues to evolve. Now, we can expect industrial operations will become more reliable and secure. Safety may start with technology, but it’s the people who make it work.